|

|

||||

Inside the laser projector |

||||

|

|

||||

|

Two GSI model G-120 scanners, with mirrors and mount. The

scanner bodies are about 1" x 1" x 0.5".

|

Scanner amp circuit board, Cambridge model 6580 (drives a

model 6800 scanner). Tuning adjustments are done using the blue trim pots.

|

![]()

![]()

The laser

projector is the heart of a graphics system. It contains the galvanometer scanners and

scanner amplifiers, which together move the beam fast enough to create graphics. It also

contains an intensity device that blanks and/or colors the laser beam. This section

discusses these two vital parts of a projector.

There can be other parts, such as beam tables and lumia

special effect devices. However, this section will concentrate on the graphics-specific

parts, since graphics are vital to today's laser shows.

Here's some essential information on what's necessary to

put together a good graphics projector.

X-Y scanners

Scanners

move tiny (3 x 5 mm) mirrors that deflect the beam. Two are needed; one for horizontal

motion (X) and one for vertical (Y). Together, they can position the beam anywhere on the

display screen.

For the most accurate graphics reproduction, use

closed-loop galvanometer scanners (they're also called "position-detecting"

scanners). The two largest companies providing these are Cambridge Technology and GSI

Lumonics (formerly General Scanning).

The mirrors and mirror mounts for the scanners may be

included with the scanners, or may be priced separately.

You also need a positioning mount. This holds the scanners

at right angles to each other, in the best orientation for X-Y scanning. You can purchase

this or machine your own. The mount design is especially important for Cambridge scanners,

as the mount must dissipate enough heat from these small, fast scanners.

Scanner amp

Each

closed-loop galvo scanner requires a closed-loop scanner amplifier, to condition and

amplify the computer's laser control signals. You can obtain the amplifiers either as

circuit boards or as fully assembled units.

Circuit board amps use trimpots for control adjustments, and

require a power supply, usually +/-15 VDC or +/- 24 VDC at 2 to 4 amps. Fully assembled

amps come in a case with 120 volt AC power supply and knobs to adjust controls. An

advantage of boards is that you save money and you can mount them inside your projector

chassis, avoiding another box to carry around.

A cable connects the boards to the scanners. You can purchase

this or make your own. The cable is usually short, to provide the most accurate feedback

signals between the scanners and the amp.

Recommended scanners

Before you

buy scanners, be sure you know exactly what you're getting. For example, you may see ads

for "abstract graphics" projectors. This term means that the projector is not

intended for accurate computer control. It usually uses open-loop scanners with simple

amps. Also avoid resonant scanners; these scan only simple patterns at fixed frequencies.

Based on Pangolin's tests and experience, we recommend that you

buy one of the following three scanners and scanner amplifiers: 1) Cambridge

Technologies model 6800 with matching amps. 2) Cambridge

Technologies model 6210 with matching amps. 3) Cambridge

Technologies model 6215 scanners and matching

amps. All of these are closed-loop

scanning systems that can reproduce the ILDA test pattern at 30,000 points per second (ILDA

30K)

or more. In the case of the model 6215, when using the

High Power amplifiers, these can reproduce the ILDA test

pattern and other laser graphics at 60,000 points per second

and thus they are strongly preferred.

We cannot recommend other types or brands of scanners for

computer graphic use at this time. This may change as Pangolin tests newer equipment.

Single-color control

Most

graphics projectors use some type of blanking device, to turn off the laser's beam as it

moves between the visible lines of a drawing. Blanking in a single-color projector can be

done with a galvo scanner, with an acousto-optic modulator (AOM) crystal, or

possibly with direct-diode modulation, if you are

using a solid-state laser.

The advantage of galvo blanking scanners is their compatibility

with galvo mirror scanners. Their on/off response time inherently synchronizes with the

galvo mirrors' movements. The disadvantage is that this response time is relatively slow.

It is not enough to simply use an arm which rotates in and out of the beam. Complex,

multi-mirror optical paths are required, so that a small movement of the blanking galvo

can instantly cut off the laser beam.

AOMs operate much faster than galvos, automatically giving

clean on/off response. Many people feel they are easier to work with, since they do not

require the optical path lengthening of galvo blanking. However, timing adjustments are

necessary in the laser software or in the AOM driver circuit so that the AOM is

synchronized with the much slower X-Y scanners. The AOM signal must lag the scanner

signal.

Direct-diode modulation can be done with certain

solid-state lasers such as diode-lasers or DPSS

lasers. The modulation rate is generally faster than

when using a galvo, but generally slower than using an

AOM. Also, there can be some power degradation when

using direct-diode modulation, which does not happen

with an AOM. Still, direct-diode modulation is

certainly a viable technique and is used by many

lower-cost laser systems.

If you are using blanking devices, work with your projector

manufacturer or component supplier to be sure the blanking system is best for your

application. Pangolin's software is adjustable, so it works with whatever blanking system

you choose.

Full-color projectors

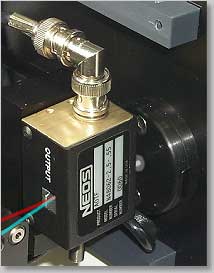

A white-light laser beam enters the PCAOM crystal from

the right, while a radio-frequency signal is injected from the top. The RF signal sets up

a diffraction pattern which acts as a prism.

|

Since

1992, most gas laser projectors use polychromatic AOMs (PCAOMs). These control both

blanking and color selection in one device. They are usually used with so-called

"white-light" beams to do full-color graphics. Since around 2002,

most solid-state lasers use direct-diode modulation.

Individual diode and/or DPSS lasers are combined

into a single "white" beam.

Color balance is important, so be sure your beam has a good mix

of colors to make a balanced white. Because the eye is more sensitive to green, there

should be more red and blue light than green.

In a PCAOM system, a white-light beam is directed into a

crystal. Signals from the computer go into the PCAOM driver, which causes the crystal to

diffract different wavelengths (color) away from the original beam. The diffracted,

colored beam continues on to the X-Y scanners.

PCAOM driver electronics come in 4-, 6- or 8-channel models.

This refers to how many wavelengths (colors) can be simultaneously controlled. Usually,

the more channels the better. For example, Pangolin's LD Pro controls up to six

channels. This lets you create unique colors such as a pure violet. It is not a mixture of

red and blue, but it is the argon's natural violet wavelength coming through.

PCAOMs have become the de facto method of color control

for gas lasers.

This is because they are simple to align, relatively inexpensive, and provide extremely

fast control. PCAOMs are so fast that each point in an image can have a different color.

(One benefit of this speed is that TV-like raster images can be created.)

Basics and add-ons

Here are

some suggested system configurations. Costs given are only for the parts in a graphics

projector; they do not include the projector chassis, laser or computer.

If you're a hobbyist on a very tight budget, start with a

simple two-scanner system. One scanner controls the X (horizontal) axis, the other

controls the Y (vertical) axis. At a minimum, you will need: two scanners with mounted

front-surface mirrors, a mount to position the scanners relative to one another, two

single-channel scanner amps (or one dual-channel amp), a power supply for the amp(s), and

a cable to connect the amps and scanners.

To give an idea of costs, the above is about $2000 using the

fastest available scanners, Cambridge Technology model 6215. Cambridge can

provide everything

except the power supply.

The system above will not have blanking. Although it is

possible to do clever drawings which hide the retrace line, most people should also add a

blanking or color control device. It is certainly easier to create images when you can

hide the beam.

A blanking projector adds a blanking device (galvo or AOM), a

driver (scanner amp or AOM driver), a bracket to hold the device in position, and a power

supply for the driver. Expect to pay roughly $500 for a monochrome blanking device and

driver. A PCAOM can be the best way to go if you are using gas lasers. At a cost of $1000 - $3000, it serves not

only to blank the beam, but to control color of all but the highest power laser beams.

Having a PCAOM gives you great flexibility to move up in power and capabilities without

buying any new equipment. If you are using solid-state lasers, often times

there is no additional cost for color control and

blanking, because this is often done directly

using the included laser diode driver.

The costs given above do not include a chassis. One important

reason to buy a fully assembled projector is that the manufacturer provides the chassis

plus additional convenience and safety features, such as a shutter. In the United States,

the manufacturer should also provide CDRH certification.

This last item means that the projector has been built to the

standards of the U.S. laser safety agency, the Center for Devices and Radiological

Health.

If you perform public shows in the U.S., you must certify both your equipment and show

sites to the CDRH. Most manufacturers of complete, turnkey projectors will include

equipment certification as part of their service.